ogp is recognized as a premier supplier of multi-sensor and non-contact measuring instruments around the world. ogp products provide solutions for applications in the automotive, aerospace, ceramic, clinical, electronic, semiconductor, plastics, biomedical, and metalworking industries, among others.

systems from ogp are used daily in over 40 countries to help manufacturers improve quality. While the instrument head moves in the X, Y and Z axes, the part being measured remains stationary.Ogp designs and manufactures precision multi-sensor and non-contact coordinate measuring systems used for dimensional inspection. Its unique carbon fiber composite X-axis beam exhibits superior noise-dampening characteristics, while its light weight contributes to measurement speed. SmartScope® Flash™ 635 (635 x 635 x 200 mm) – Provides measurement speed and stability. This design assures rapid, smooth part translation and robust measurement performance. An extended Y-axis travel of 610 mm is optional and either 300 mm or 400 mm extended Z-axis travel is available. Parts move on a precision DC motor-driven Y-axis stage while the optics assembly travels in the X-axis across a stable bridge cross member. SmartScope® Flash™ 500 (Contact us for XYZ Stage Travel details) – Offers all the great Flash features and performance in a large, travel bridge-design system. It also comes standard with a TTL coaxial illuminator and patented LED SmartRing™ light. A high-quality auto calibrating AccuCentric® 12:1 zoom lens provides excellent optical performance over its entire range. It contains a unique “elevating bridge” design and axial straightness and perpendicularity are built in to meet stringent volumetric specifications. Add optional through-the-lens (TTL) laser, touch probe or micro-probe to configure a highly capable multisensor system.

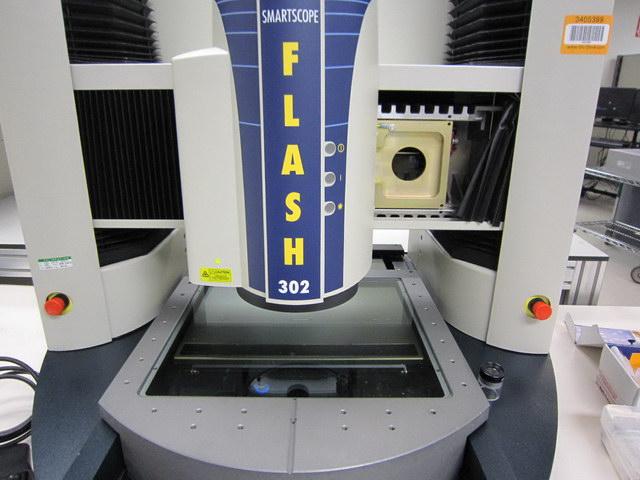

With an expansive Z-axis of 250 mm (10 in.) to accommodate large parts, it combines state-of-the-art video and autofocus to deliver high productivity. SmartScope® Flash™ 302 (300 x 300 x 250 mm) – One of the most versatile benchtop systems OGP offers. It’s ideal for a wide variety of manufacturing industries including metalworking, plastics, biomedical, electronics, automotive, aerospace and more.

#Smartscope flash 200 user manual software#

Its heavy cast base and rigid steel column provide metrology integrity so accuracy can be maintained in real world environments. Like all Flash systems, it is equipped with OGP® Measure-X® metrology software and 12:1 AccuCentric® zoom optics. Its large 300 mm X travel makes it the system of choice for measuring critical dimensions of long parts on a benchtop machine.

SmartScope® Flash™ 250 (300 x 150 x 200 mm) – A compact machine designed for easy access to the XY stage for maximum fixturing flexibility. SmartRing™ light is standard for the ultimate flexibility in surface illumination. The computer controlled LED array backlight tracks X-axis motion of the optics with no moving parts. It also has patented innovations that let users do more, faster.

Innovative design features of “elevating bridge” and an embedded computer mean the system takes up little space on a benchtop while providing an ample measuring range and extensive measurement capabilities. SmartScope® Flash™ 200 (200 x 200 x 150 mm) – The smallest member of the Flash family of systems is a full-featured automatic measurement system.

0 kommentar(er)

0 kommentar(er)